Creative Technologist.

Current MDes Mediums Student at the GSD.

Contact me

You can reach me at

alexiaasgari@gmail.com

Fall 2019 | Professor Jenny Sabin |

Non-prective SLA 3D Printing was presented as a finalist at the Cornell Undergraduate Research Board 2020 Fall Forum

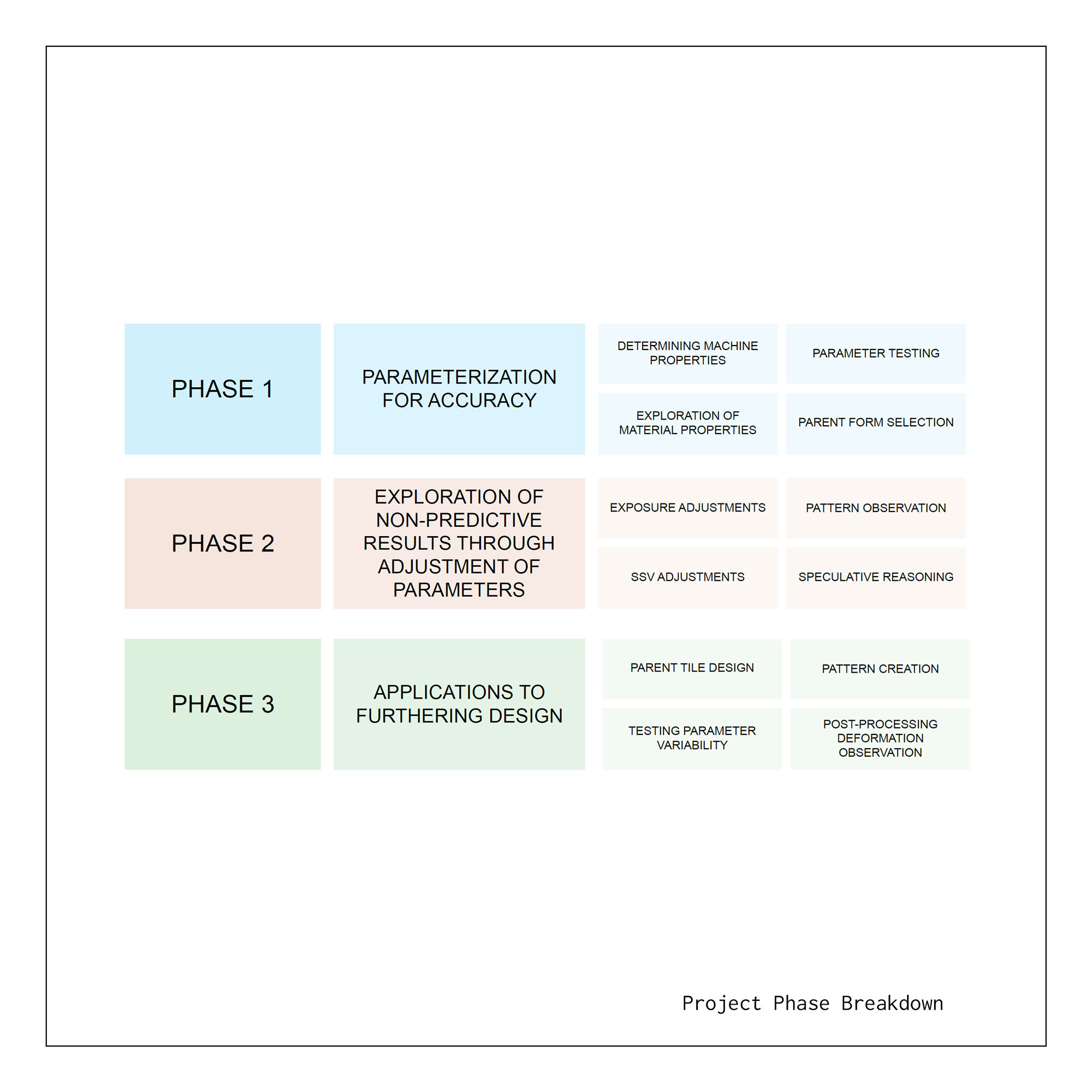

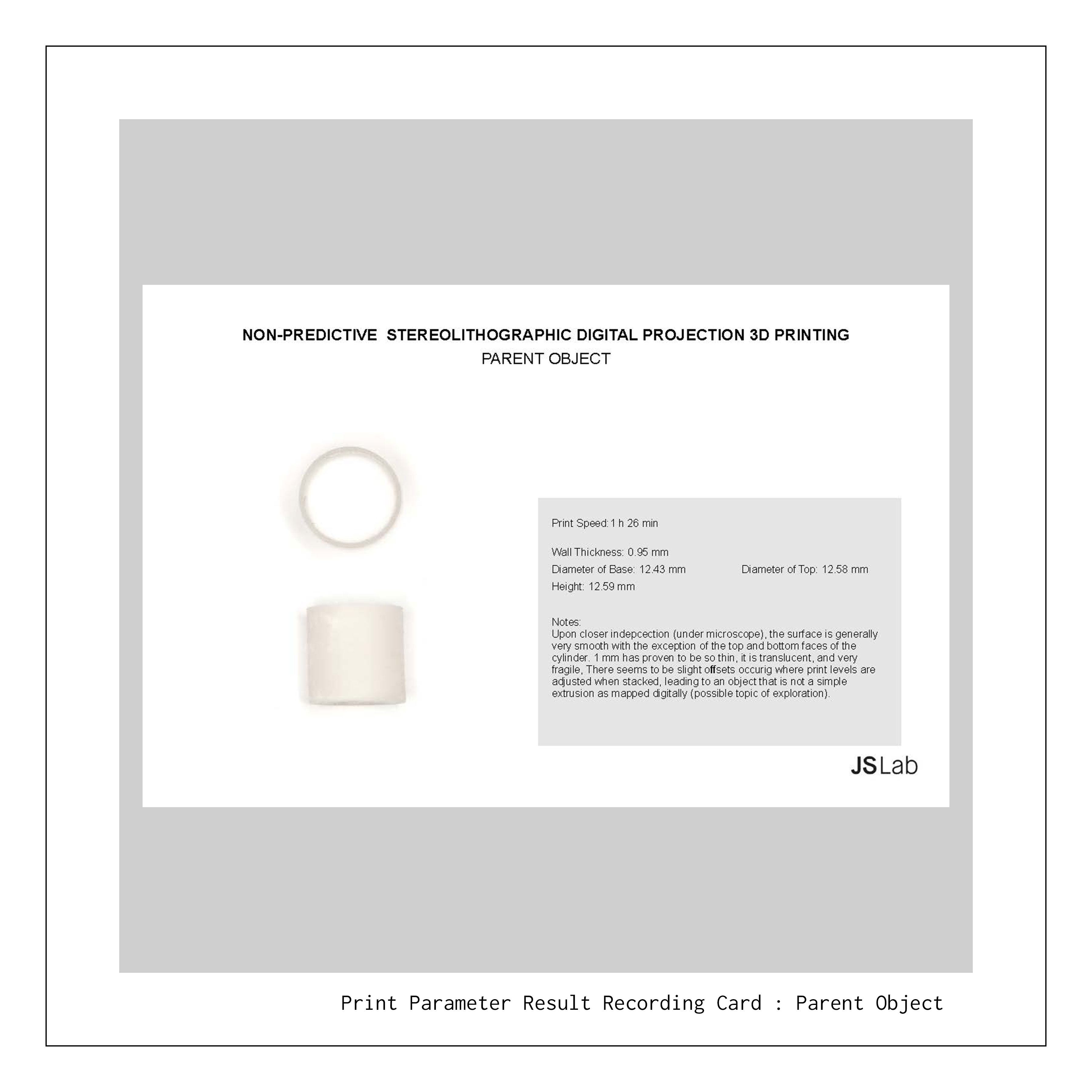

This research project served as my initial exploration into the potentials of non-predictive additive manufacturing. Stereolithographic Digital Light Projection Printing has been under-explored in the field of 3D printing research. Parameters function differently to filament deposition printing, as explained in the figures below. These different parameters present new territory for investigation, allowing unique results when skewed. Non-predictive printing aims to position 3D printing as a tool for the initial stage of the design process, rather than just a simple representation tool, replicating exactly what is on screen.

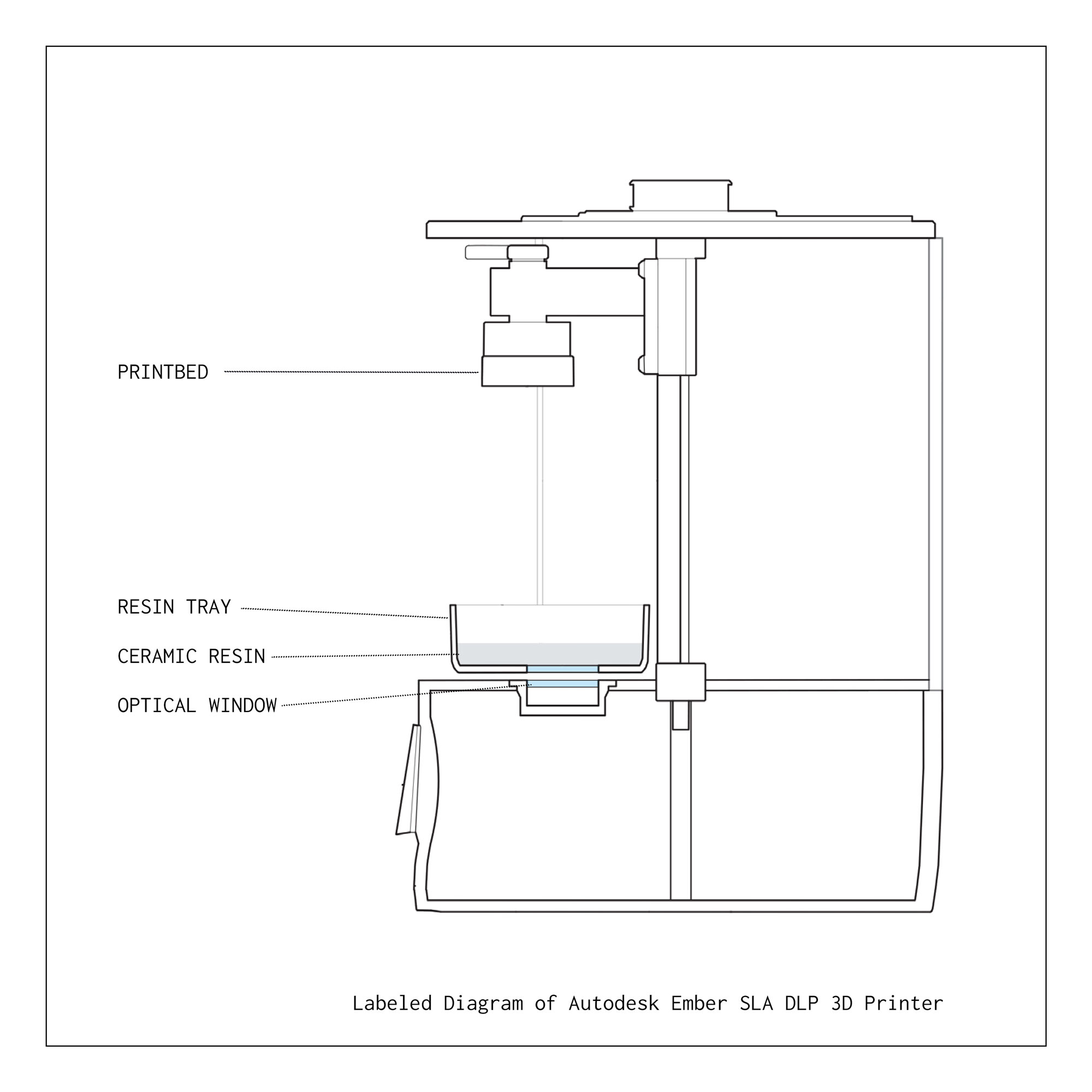

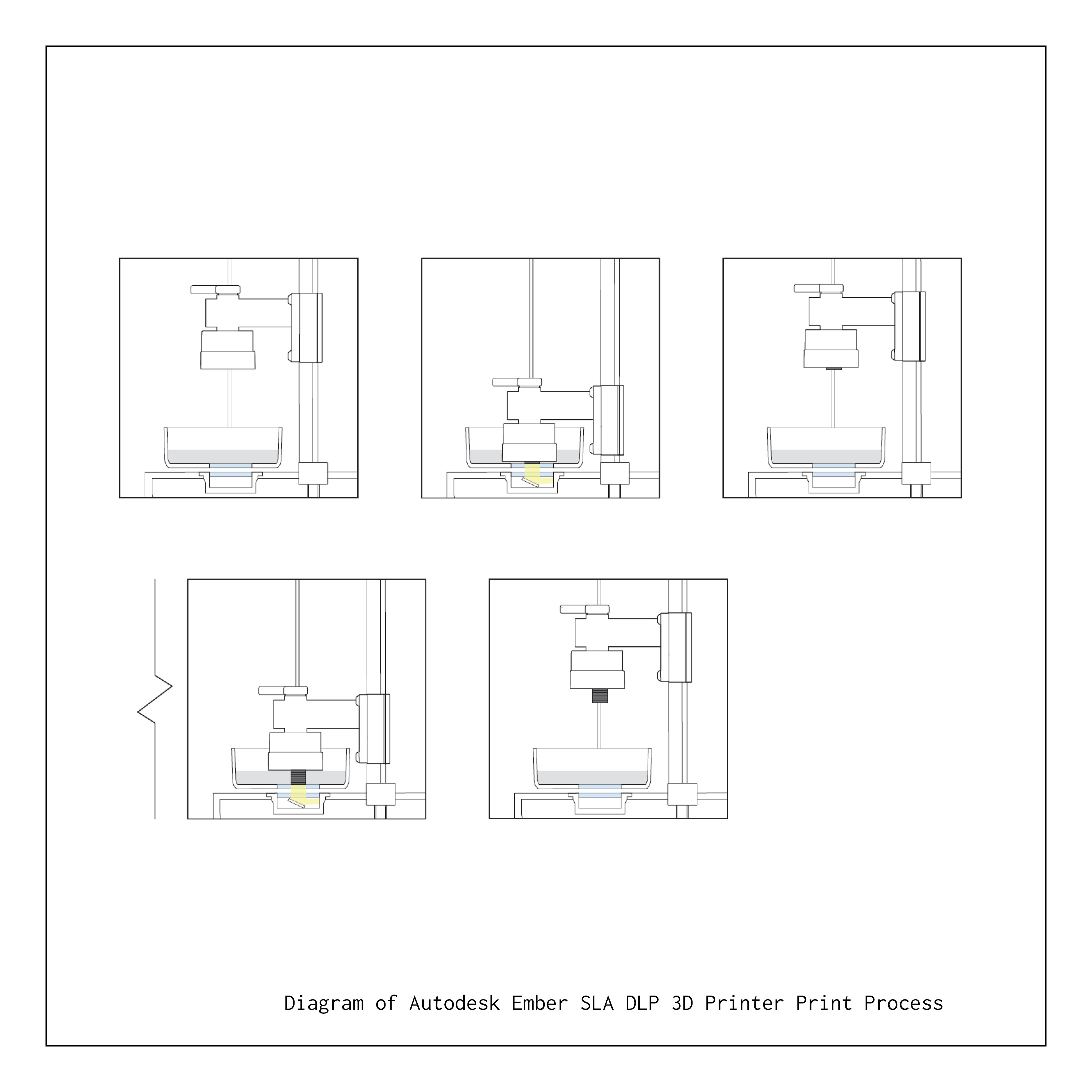

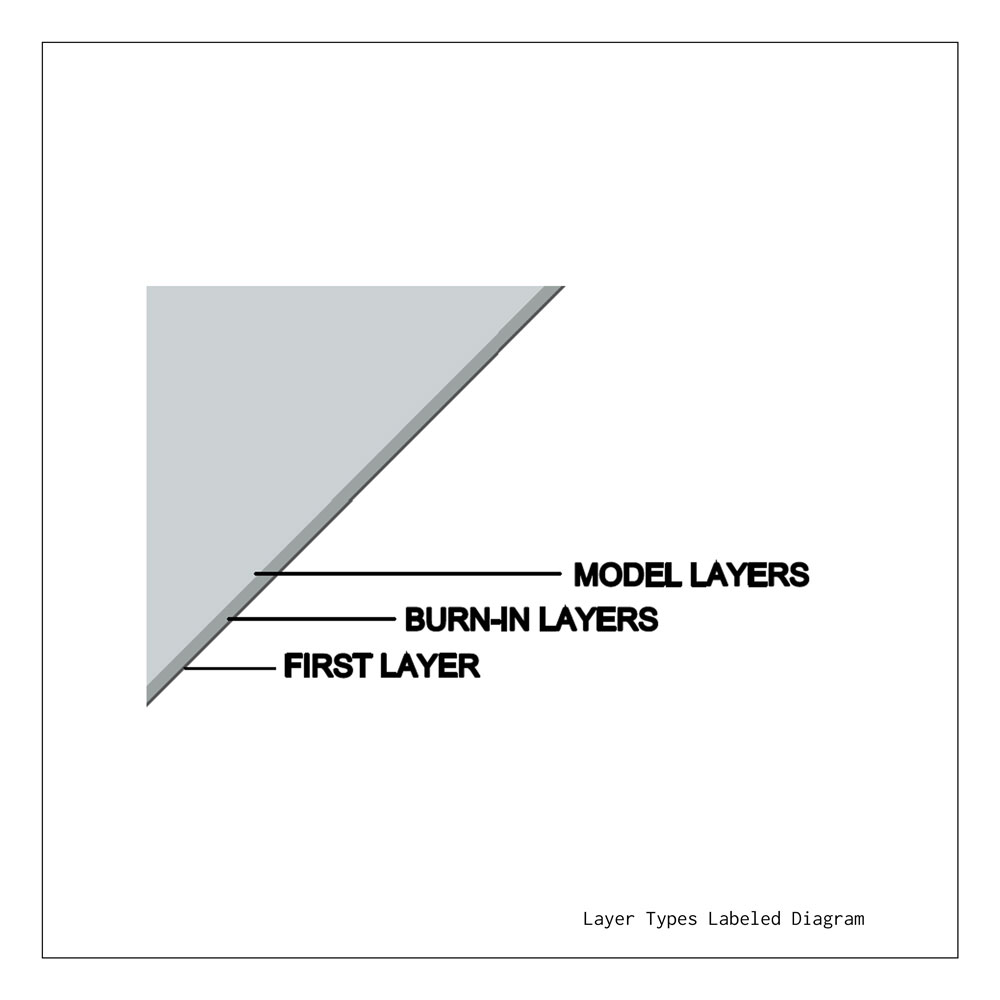

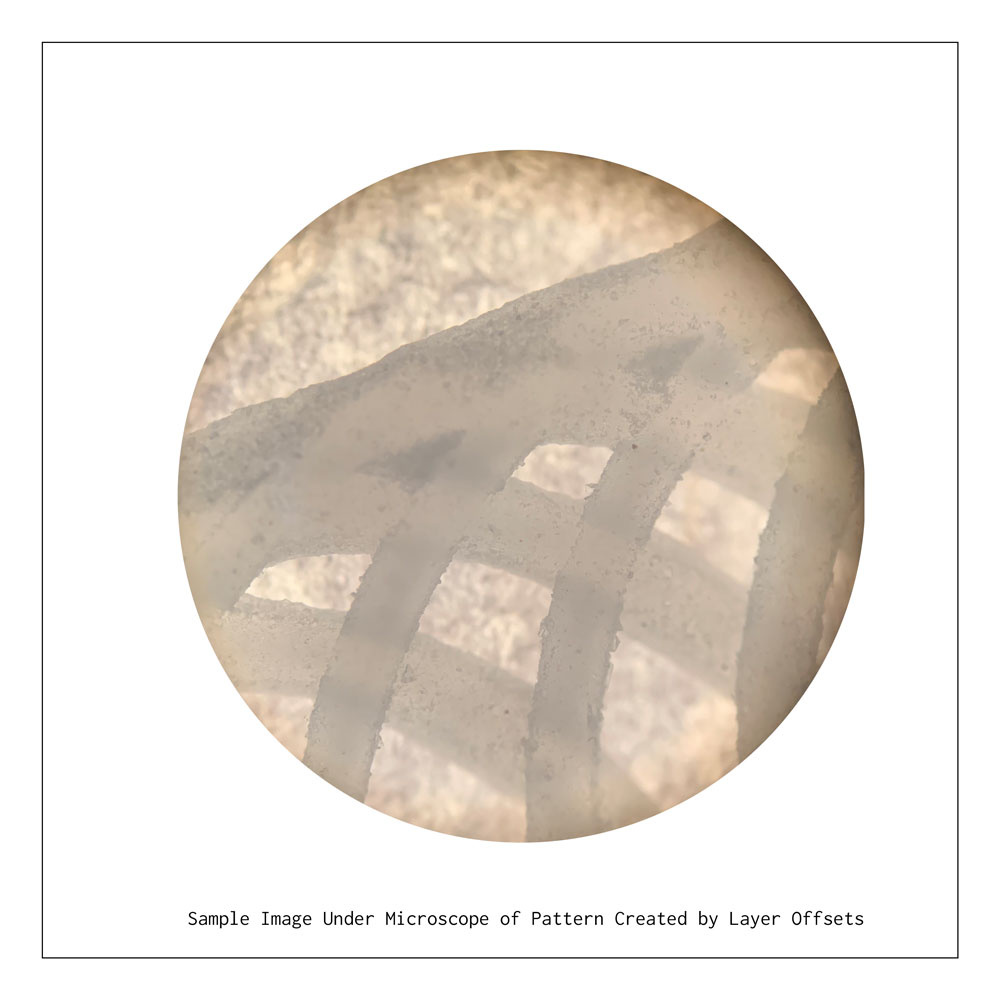

The Autodesk Ember is a digital light projection 3D printer. It functions by dipping the print bed into a vat of resin and curing it by projecting the layer pattern onto the optical window at once. After each layer is cured, the print bed moves upward, making room for the next. Exposure time and Z-axis movement parameters hold a strong influence on this process. The machine also uses a rounded sliding motion to delaminate the print from the optical window between layers. This is called the separation slide and is controlled by parameters such as the separation slide velocity. Because of the many precisely angled mirrors for projecting light in the Ember, the system can print with an accuracy of up to 10 microns. Prints can be very small and accurate on this system.

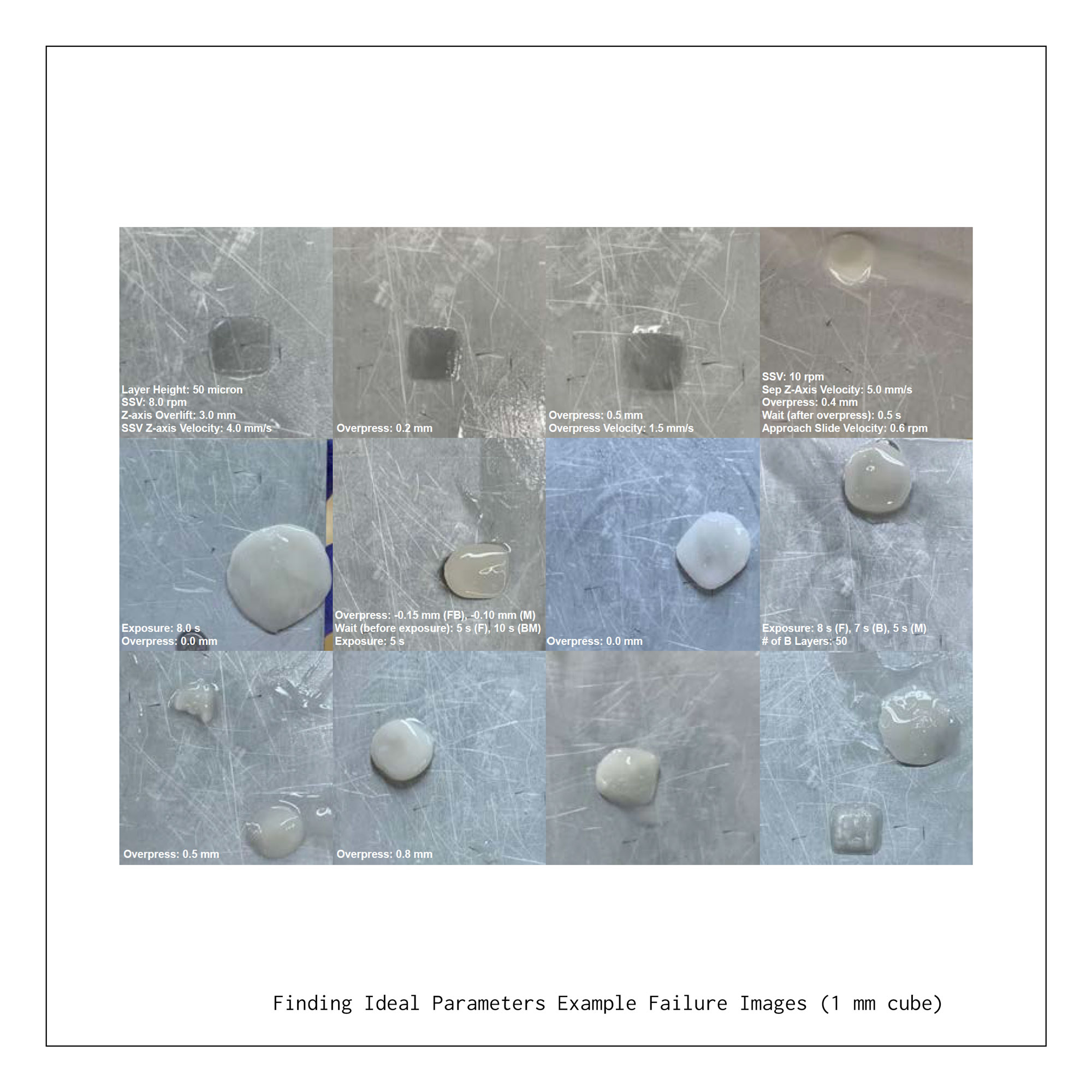

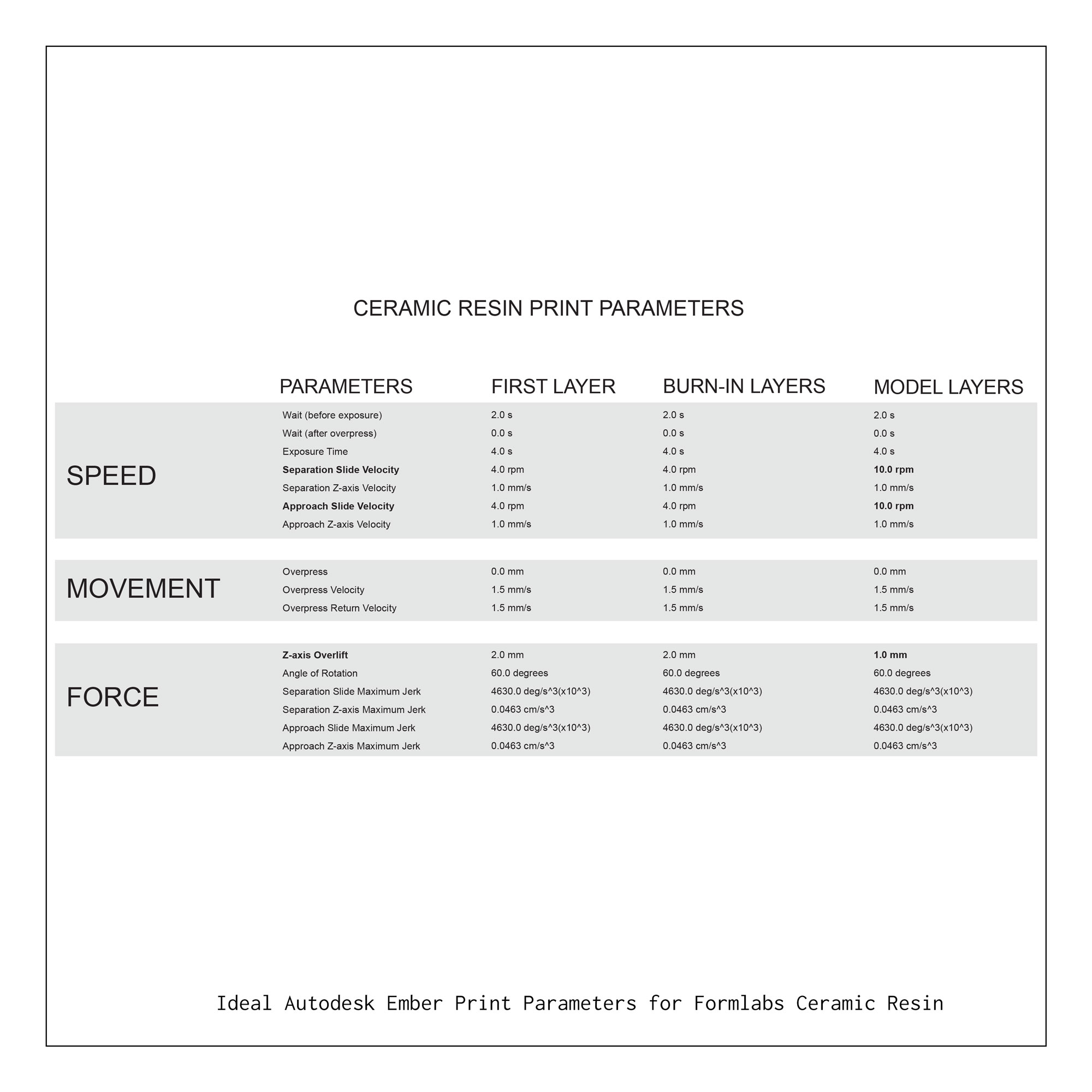

The process began by finding ideal parameters. Using the Autodesk Ember at a time after it was discontinued, meant there were minimal resources online. In order to use the Formlabs Ceramic Resin (not native to the Ember machine), I had to conduct rigorous testing to see which parameters would perform best with the machine.

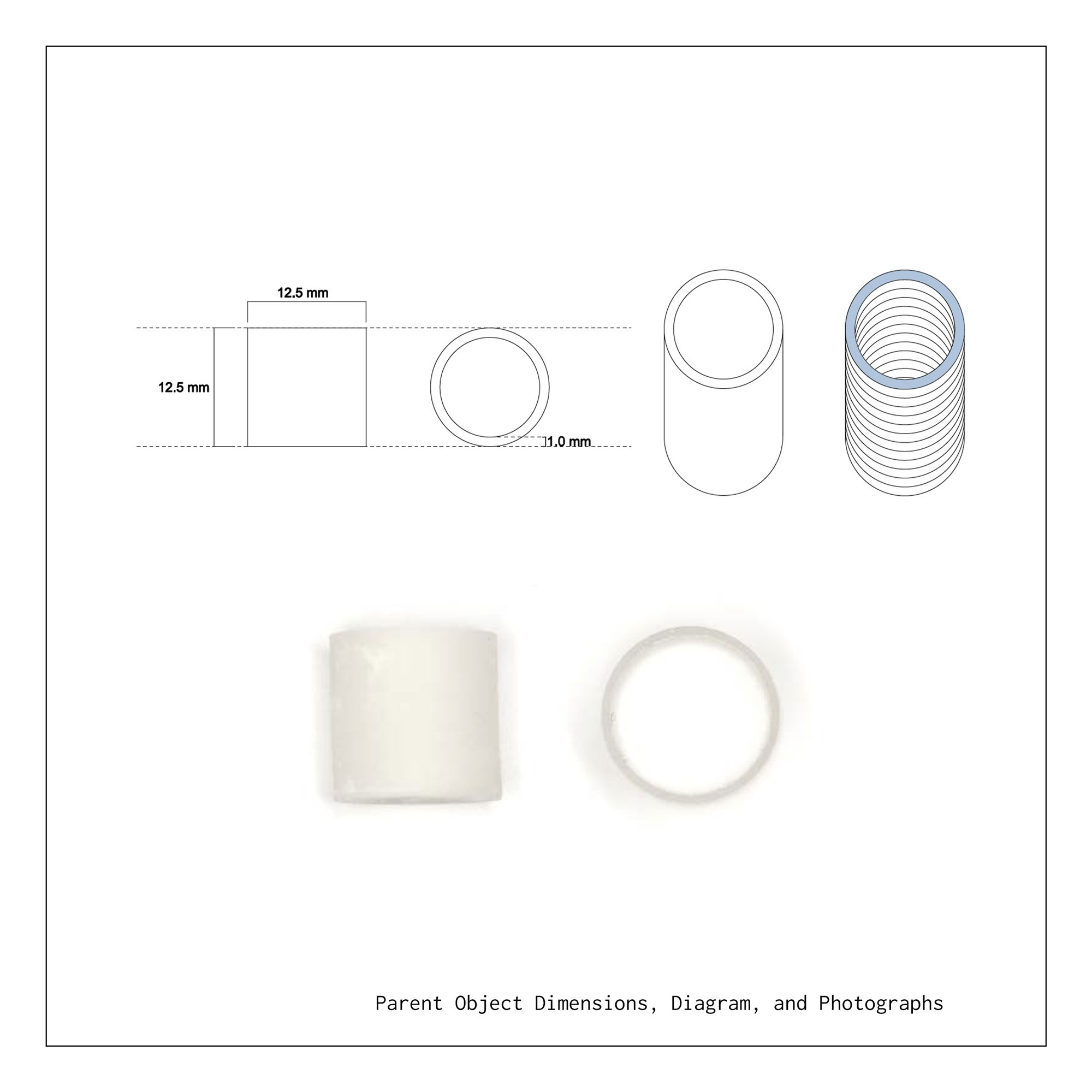

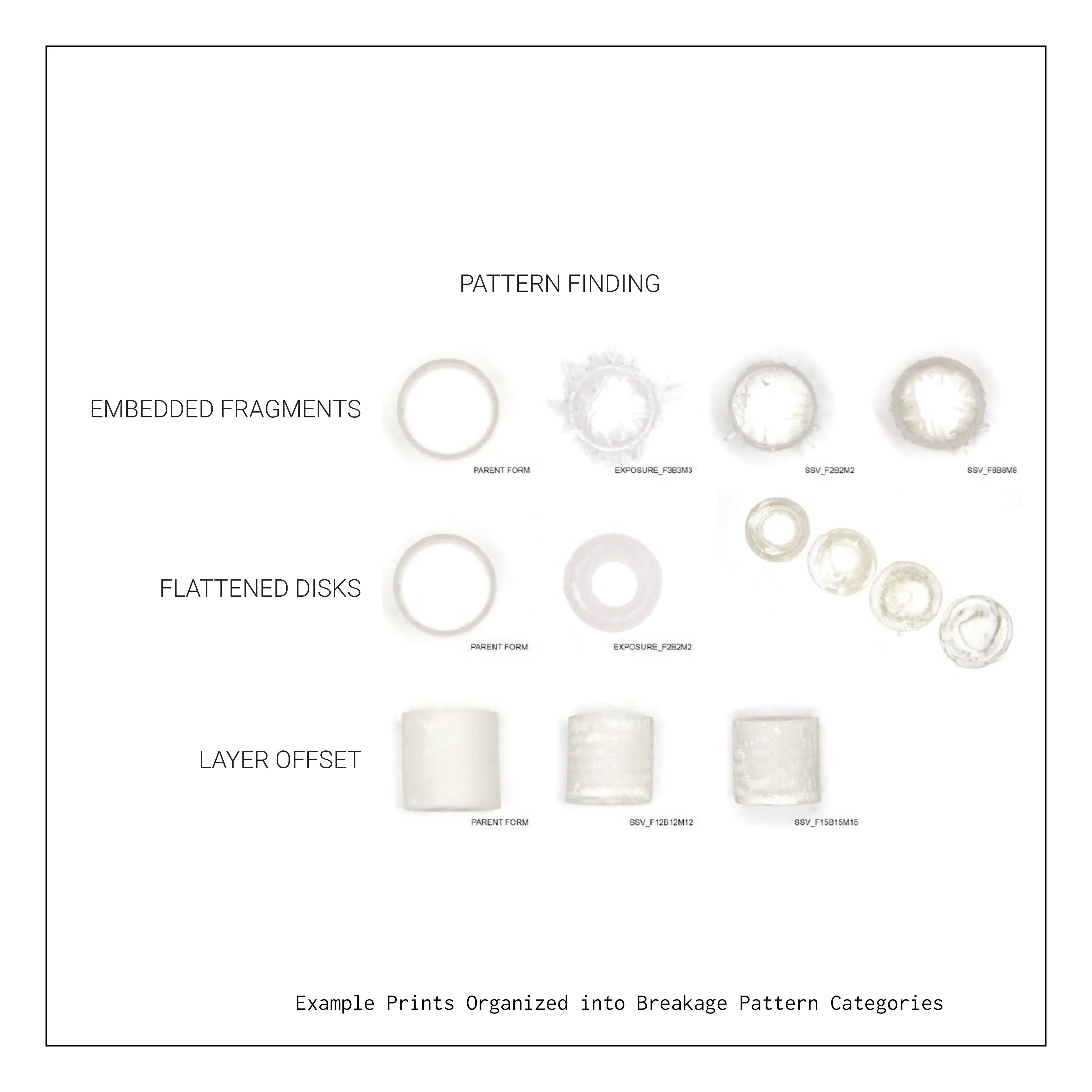

For a parent object, I was inspired by the work of Benay Gursoy and chose to use a simple hollow cylinder. Because of the digital light projection process, having an object consisting of many identical layers would best enable me to compare breakages. With each print series, I would adjust a singular parameter, otherwise maintaining the ideal parameter settings listed above. Mere seconds marked the difference between printable objects and not in this fragile process. In the delicate balance between ideal prints and entirely non-printable objects, I was able to find beautiful patterns of breakage. I classed them into 3 categories: